Tel:86-769-85628130

We have rich industry experience and have accumulated 12 years of experience in the field of industrial automation since our establishment. This enables us to gain a deeper understanding of the needs and challenges of various industries, and provide the most suitable solutions for our customers.

We always adhere to the concept of quality as the core, and strive for excellent quality in every project. We collaborate with top-notch suppliers, using high-quality materials and advanced technology to ensure that our automated assembly line solutions have excellent performance and reliability.

We have a professional team composed of experienced engineers and technical experts. They possess extensive knowledge and skills to design, develop, and customize various types of automated assembly line solutions. Whether it's a simple production line or a complex production system, our team can provide practical and feasible solutions.

We attach great importance to customer satisfaction and long-term cooperative relationships. Therefore, we provide comprehensive after-sales service, including training, technical support, equipment maintenance and upgrades, etc. Our goal is to ensure that customers can fully utilize our automated assembly line solutions and receive continuous support and assistance during use.

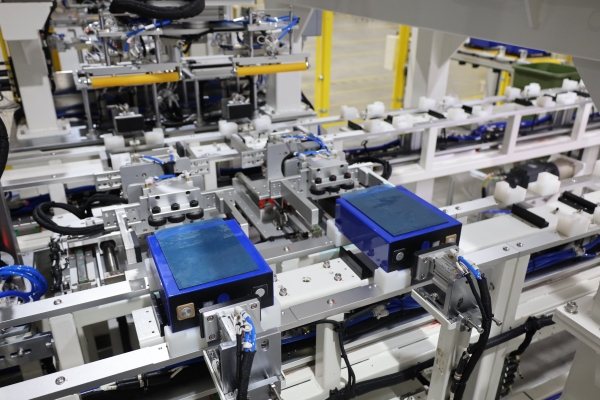

This equipment is used to achieve automated packaging of finished battery cells and integrate the equipment with upstream and downstream systems.

Detail

This production line is an automated assembly line for rectangular energy storage modules, completing the automated production process from battery cells to energy storage batteries.

Detail

This production line realizes PACK-EOL testing, charging and discharging tests, utilizing AGV logistics conveyor lines to transport the boxes to various testing stations.

Detail