Core Technology

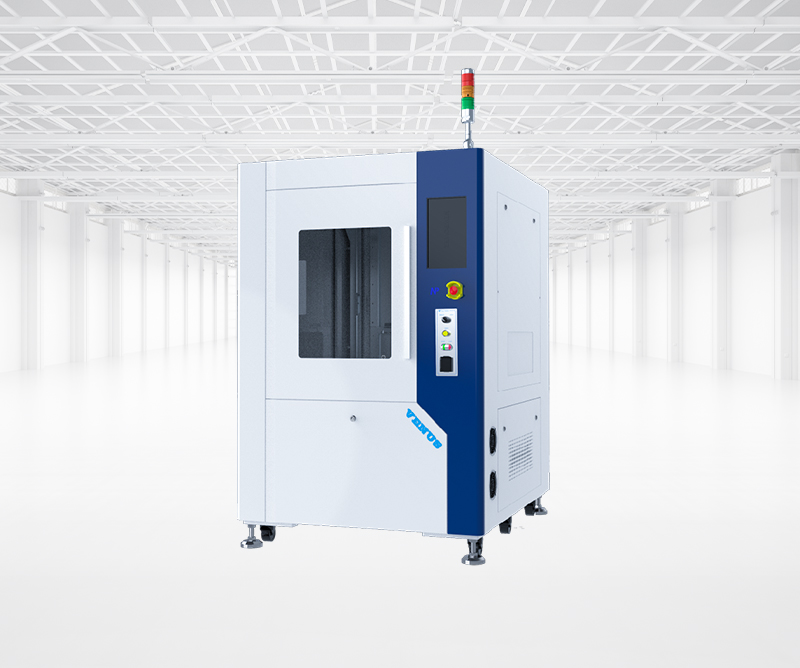

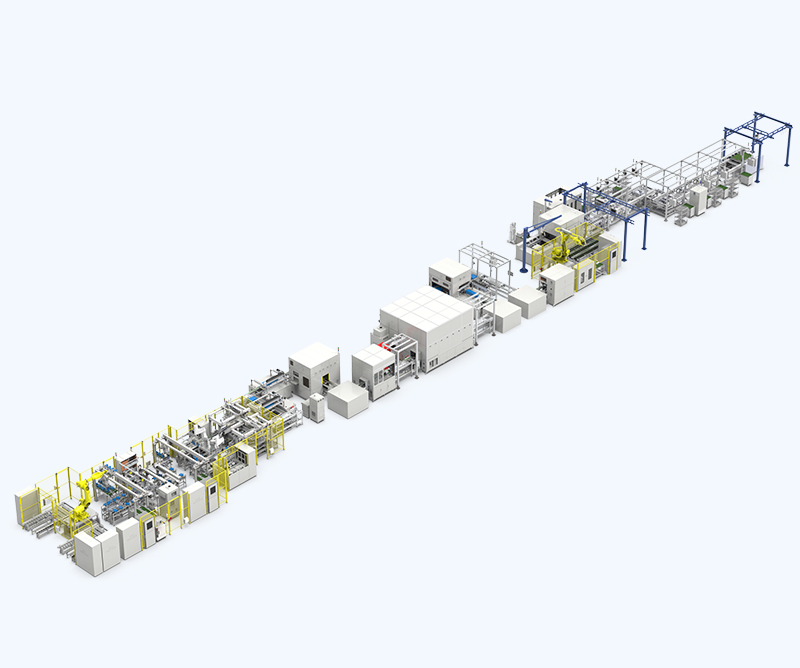

The industry's first modular design, standardized platform, and embedded software development platform (C # Platform).

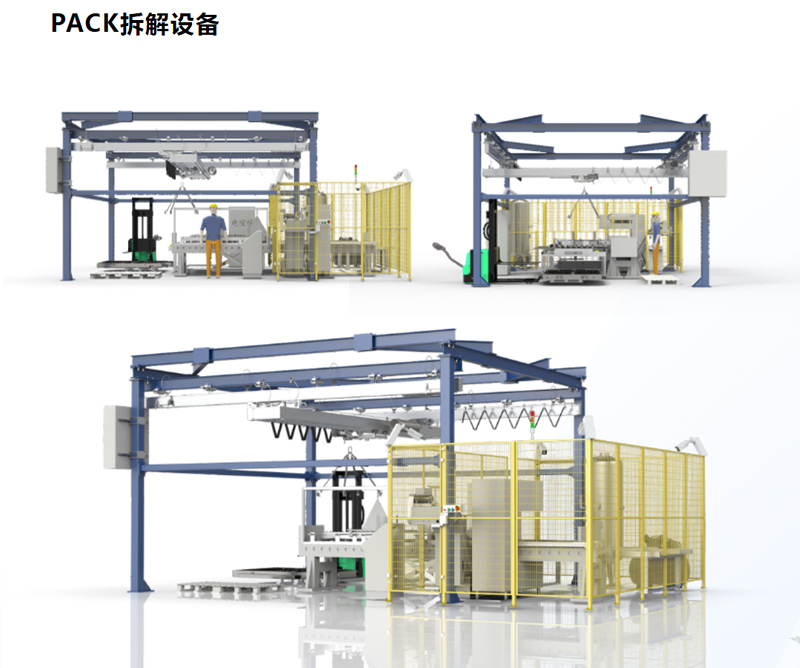

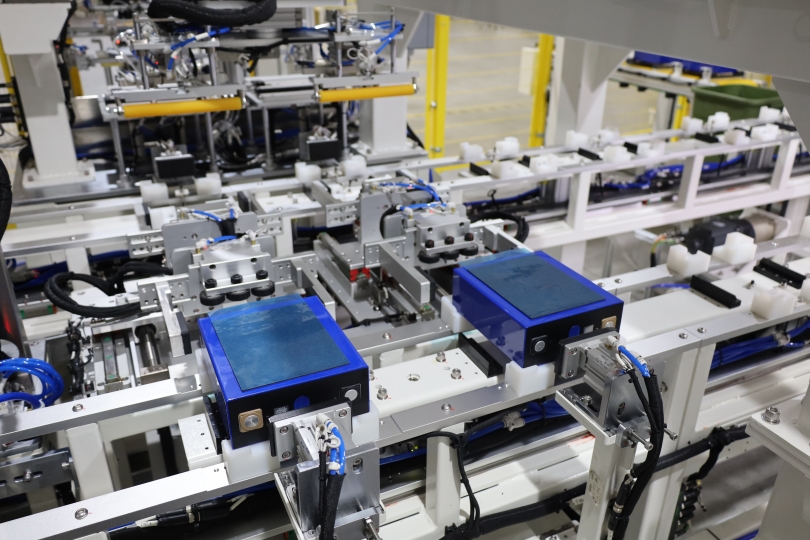

Flexible design, embedded in the most commonly used applications in the industry, such as screw locking, gluing, laser marking, welding, labeling retrieval, testing, etc.

Quick change of applications can achieve "one machine with multiple functions", which is suitable for both high volume mass production and high mix low volume production.

Software with independent intellectual property rights - Alpha Pro (C #) patent number: 2018SR4639172018SR463941